Displaying items by tag: space systems

Alta SpA

Alta is a leading European small company in the aerospace propulsion sector. We operate in research and development on space electric propulsion, chemical propulsion andaerothermodynamics. Our company provides testing services, high vacuum systems and facilities and space systems design and computational simulation tools. With a successful record of technology transfer cases, we are also active in the energy and industrial plasma sectors.

With propulsion systems suited to a variety of missions - from interplanetary probes to low-cost microsatellites - Alta covers the broadest EP technology range among European companies. Alta’s researchers and engineers make up the largest and most experienced European R&D team working on EP, with know-how and capability in all EP application fields.

- Hall Effect Thrusters

- MagnetoPlasmaDynamic Propulsion (MPD)

- Field Emission Electric Propulsion (FEEP)

- Resistojet Propulsion

- Diagnostics for Electric Propulsion

Alta’s excellence in Electric Propulsion (EP) technologies is demonstrated by a long record of achievements:

- 1974: first European Pulsed Plasma Thruster

- 1980: first European quasi-steady Magneto-Plasma-Dynamic Thruster

- 1994: first European Hall Effect Thruster

- 1999: first integrated FEEP micro-thruster

- 2001: first European high power Hall Effect Thruster

- 2004: first European miniaturized Hall Effect Thruster

- 2005: largest European electric propulsion testing facility

Concurrent Design Platform (CDP)

“CDP™ made by engineers for engineers. It does what it needs to do,.... and more !”

The J‑CDS Concurrent Design Platform (CDP™) is the main engineering tool to support multidisciplinary teams to perform Concurrent Design in cooperation with and participation of the customer. It provides all the required integrated design and modelling capabilities to support the multidisciplinary team in their collaborative work, allowing them to come up with a solution for the customer, taking into account the full life cycle perspective of the system.

Concurrent Design

Concurrent Design is a systematic approach to integrated product design that emphasises the response to customer expectations and the combination of creativity and engineering. It embodies team values of cooperation, trust and sharing, in such a manner that decision making is by consensus, involving all perspectives in parallel, from the beginning of the product life cycle.

Concurrent Design focuses mainly on the early phases of a project or product, such as preliminary design and feasibility studies. The central principles of Concurrent Design are

- A multidisciplinary team working together to exchange, share and discuss all aspects of a design

- A structured and guided design process

- The presence of the customer providing feedback on the main design and trade-off decisions

- Using one common reference model

- Turning multidisciplinary design sessions into concrete values supported by experts

- Representing all perspectives of the product life cycle

The outcome of Concurrent Design provides management with a very good and complete view of the system/product, thus facilitating their decision-making processes and as such reducing the overall risk of the project from the start.

Concurrent Design has proven to be a powerful design methodology for the early design phases of multidisciplinary projects. It is applicable to a wide variety of projects and industries. Activities have been performed by J‑CDS for complex system design, for Concurrent Design for System-of-System Architectures, for proposal creation, tender evaluation and planning design. One-off projects can be equally well supported as recurring feasibility studies. Multidisciplinary teams have been involved ranging from only customer internal teams to teams involving participants of various independent SMEs, companies and research institutes. Topics are as varied as housing design in the construction sector, medical equipment, small-series electronics and complex satellites within Europe’s leading space companies. The collocated design sessions for projects have been performed in locations ranging from sufficiently equipped meeting rooms to dedicated Concurrent Design facilities.

To implement Concurrent Design in industries as varied as Space, Defence & Security, Oil & Gas Infrastructure & Construction or Electronics, J‑CDS customises the process, the tools and the implementation according to the specific projects or industries.

Objectives of the CDP™

The objective of the J‑CDS Concurrent Design Platform (CDP™) is to support multidisciplinary design teams to perform Concurrent Design. The CDP™ is designed and built by users and engineers for users and engineers.

The CDP™ is a web enabled distributed Concurrent Design tool which is fully scalable and customisable. The CDP™ provides the required integrated design and modelling capabilities to the multidisciplinary team.

Customer Benefits

Concurrent Design and the CDP™ give various advantages and benefits

- Reduction of design/engineering time → product cost and lead time → Time To Market

- Increase in profitability

- Improvement in competitiveness

- A tool compliant with the Concurrent Design methodology

- Standardization of design results and methods

- Build-up of corporate knowledge in model (maximise re-use)

- Increase design control and audit trail

- Reduction in number of engineering changes during next phases

- Evaluate more product options

- Increase in involvement among employees

- Increase in employee efficiency

- Improvement in product quality

- Higher customer satisfaction

- Reduction of overall risk in the project

Overview of the CDP™ capabilities and features

The CDP™ contains the principles of Concurrent Design as an integral part of the tool to reach these objectives.

The CDP™ is used to create an integrated parametric design with supporting calculations specific to the industries standards and data models. The CDP™ is a flexible and reliable tool for the early design phases of projects, focused on allowing a multidisciplinary team to create and share up-to-date design information.

The CDP™ is able to support a design team in the early design phases with the following key capabilities. The CDP™

- Provides a collaborative working environment

- Work compliant with the Concurrent Design methodology

- Provides a clear audit trail in the design process

- Allows customer participation and access to the design information in the CDP™

- Allows the multidisciplinary team to work on the project. Access possible for

- Collocated teams through an intranet connection

- Geographically distributed teams through internet connection

- Supports requirements discovery by the team together with the customer

- Create a structured list of requirements in the CDP™ Requirements Manager

- Allows to monitor the status of the design, checking against the requirements

- Linking requirements to the design in the CDP™ Requirements Manager

- Allows to build a common and shared data model

- Parameterised model in CDP™ Product Tree

- Reuse of modelling elements through CDP™ Activity Library

- Allows to manage the design team in the design activity

- User management with ability to define roles with appropriate rights, according to the needs of the organisation or project

- Management of the technical and non-technical disciplines assigned to users

- Allows to investigate and assess various design solutions with configuration control

- Management of the design cycle through options and iterations management

- Allows to assess various design solutions and track progress in the design work

- Allows the stringent control of data flow

- Control the flow of information exchange through e.g. publishing and request mechanisms

- Allows to store and manage additional sources of design information and data

- Storage and management provided by the CDP™ Document Management System

- Allows to prepare and synthesize CD Activity information on all levels for all team members

- Overview provided by the Concurrent Design Synthesis Dashboard (CDSD™)

- Supports the customer in taking a decision on the most promising solution direction

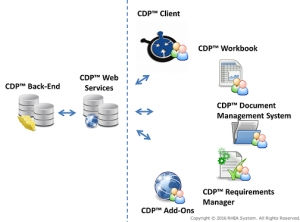

The CDP™ architecture and features

The CDP™ consists of several components.

The CDP™ Back-End is a structured storage of all the data, providing easy and secure access to data. The Concurrent Design methodology is embedded in the structure of the database.

The information is accessed and managed through the CDP™ Client as main modelling tool. It provides various features and functionalities for administrative actions in a CD activity, e.g. user management, activity management, data exchange control and session management, including session checklists, minutes of meeting and action assignment. Furthermore it supports engineering actions, e.g. setting up and using the design model, tracking parameters and tracing the compliance of the requirements, with the ability to link these to design parameters in the various solution directions.

The team members make use of Microsoft Excel® spread sheets as their engineering work space. These CDP™ Workbooks provide a filtered view on the complete data model in the CDP™ Back-End that allows the engineer to perform design work and calculations within their domain and share that the necessary information with the other team members. This interaction is managed by CDP™ input and output sheets as interface to the CDP™ Back-End. These CDP Workbooks can be customised to include models and calculation sheets for specific disciplines, as well as to provide links between the CDP™ Workbooks and external tools, e.g. other Microsoft Excel® spread sheets, 3D tools such as CATIA, simulation and calculation tools such as Simulink® or MATLAB®.

Additional modules are available integrated into the CDP™ or as self-standing tools with the possibility to interact with the CDP™. The CDP™ Requirements Manager is used to provide traceability of requirements throughout the design activity. Next to the design information in the parametric model itself, the CDP™ has an integrated Document Management System (DMS) to keep track of a wider source of related project information, with possibilities to link these to the actual design model for a better understanding. An example of a self-standing tool is the J‑CDS Stakeholder Value Mapper, to be used for stakeholder analysis in projects. This tool allows to identify stakeholders and their associated goals, values and requirements in a project.

The Concurrent Design Synthesis Dashboard (CDSD™) provides a constant overview to the system engineer and domain engineers in a Concurrent Design activity of the key design information and the status of the process. It combines a set of tools related to the different phases of the CD activity (i.e. initiation, preparation, study, reporting) and visualizes key information. The CDSD ™ consists of 2 main parts, a dashboard view and a toolbox. The CDSD ™ fulfils the need of the team to have an intuitive view of and access to key design information and progress at all times.

The CDP™ Forum provides an additional layer of interaction, giving the team members providing access to the design information from the CDP™ Back-End, see action lists, minutes of meeting and session information as well as providing opportunities to interact in online discussions.

Key technical information

The CDP™ has regular updates, improving the user experience and adding new functionalities based on best practices from industry and user requests.

Client software prerequisites

- Supported operating systems in general: Windows XP, Windows Vista, Windows 7

- Microsoft Office 97-2003, 2007 or 2010 (32-bit version)

The CDP™ server can be hosted by J‑CDS or installed at the customer location. The CDP™ can be set-up to run secure over the internet using SSL.

Contact

For more information about J-CDS and/or about this product please contact us via arne.matthyssenADDj-cds.nl.

Ball Aerospace

Ball Aerospace & Technologies Corp. (commonly Ball Aerospace) is a manufacturer of spacecraft, components, and instruments for national defense, civil space and commercial space applications.

This American company is a wholly owned subsidiary of Ball Corp., with primary offices in Boulder and facilities in Broomfield and Westminster in Colorado, with smaller offices in New Mexico, Ohio, Georgia, Northern Virginia, and Maryland.

Ball Aerospace began building pointing controls for military rockets in 1956, and later won a contract to build one of NASA’s first spacecraft, the Orbiting Solar Observatory. Over the years, the company has been responsible for numerous technological and scientific projects and continues to provide aerospace technology to NASA and related industries.

Astrium

Astrium is an aerospace subsidiary of the European Aeronautic Defence and Space Company (EADS). It provides civil and defence space systems and services.

In 2008, Astrium had a turnover of €4.3 billion and 15,000 employees in France, Germany, the United Kingdom, Spain and the Netherlands.